Fused Deposition Modeling (FDM)

Endless possibilities with quick turnaround

Do you need quick, affordable and high stiffness 3D Prints? Then FDM is perfect for you. The FDM print layers are visible and have a limited dimensional accuracy, but 3D Printing with FDM is perfect when having a large number of iterations. With FDM, you will achieve low-cost rapid prototyping.

Manufacturing characteristics

Great tolerances of +/- 0.5 mm

FDM allows you to create almost any shape, with some rough finishes.

Maximum part size: 300x300x400 mm

You can print parts of the size that fits your needs. There are limits of course, but small and large parts are both done well by FDM

Layer height of 150 - 280 micron

While FDM does not have the highest resolution, the layers can become really thin. Pictured above is one 150 micron layer of an FDM printed ring.

Strong infill that saves material

You can choose the infill pattern and density of your parts to increase strength and reduce costs. Resulting in lighter parts that are finished even more quickly.

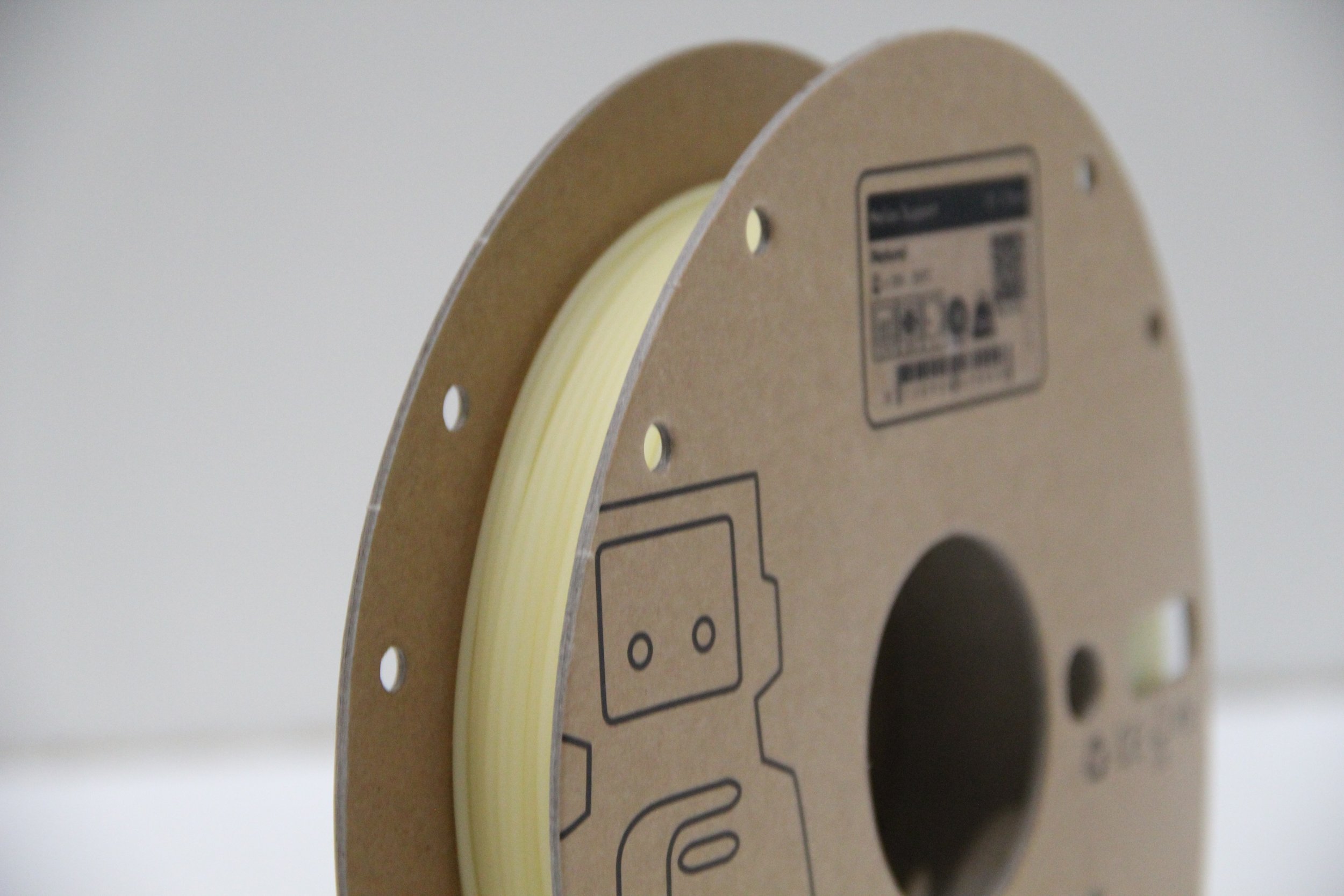

Choosing the right material

PLA

Simple. Versatile. Low Temperatures. Rigid.

PLA stands for polylactic acid and is a biodegradable thermoplastic. It has a heat deflection temperature of 40 degrees Celsius. PLA has a high stiffness and good detail. It is by far the most affordable 3D print material. Use it for moving or non-moving parts that need to hold their shape. When bent, PLA is brittle and will break at too high loads.

PETG

Sterilizable. Flexible. High Impact. Chemically And Moisture Resistant.

PETG stands for Polyethylene Terephthalate Glycol. It is a great material for mechanical parts with high impact resistance and flexibility. PETG is a thermoplastic with improved properties over PLA, with high impact resistance and excellent chemical and moisture resistance. PETG can easily be sterilized. It can handle greater forces than PLA before breaking and bends back from reasonably large deformation.